The Bullwhip Effect is a phenomenon in supply chain management where small fluctuations in demand at the retail level cause progressively larger fluctuations in demand at the wholesale, distributor, manufacturer, and raw material supplier levels. This effect is named after the way the amplitude of a whip increases down its length. The concept is crucial in understanding supply chain dynamics and for managing supply chains more effectively.

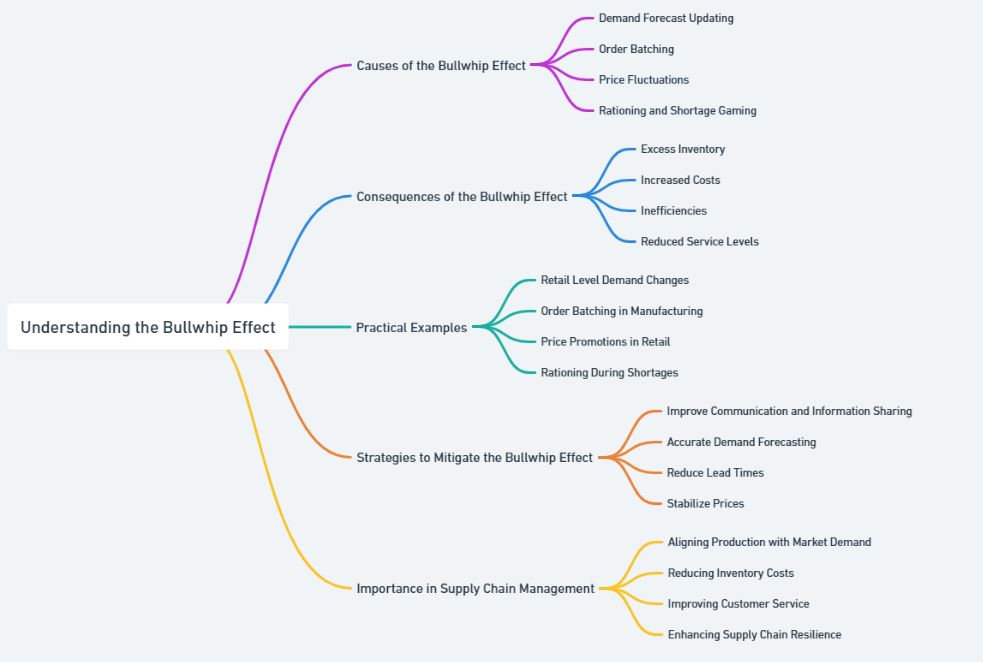

Understanding the Bullwhip Effect

- Causes of the Bullwhip Effect:

- Demand Forecast Updating: Changes in consumer demand can lead businesses to adjust their forecasts, often amplifying the original change.

- Order Batching: Companies often place orders in batches to save on ordering costs, leading to variability in order sizes.

- Price Fluctuations: Sales and discounts can lead to increased buying, which may not represent long-term demand changes.

- Rationing and Shortage Gaming: When product shortages occur, companies might order more than needed to ensure they receive enough, anticipating future shortages.

- Consequences of the Bullwhip Effect:

- Excess inventory, increased costs, inefficiencies, and reduced service levels can result from the bullwhip effect. It can lead to a misalignment between supply and demand, causing either stockouts or overstock situations.

- Strategies to Mitigate the Bullwhip Effect:

- Improving communication and information sharing across the supply chain can help reduce uncertainty and variability. Implementing more accurate demand forecasting techniques, reducing lead times, and stabilizing prices are other strategies to mitigate the effect.

Practical Examples of the Bullwhip Effect

- Retail Level Demand Changes:

- A sudden increase in consumer demand for a product at the retail level leads to larger proportional increases in orders from retailers to wholesalers, wholesalers to manufacturers, and manufacturers to suppliers. This can result in overproduction and excess inventory throughout the supply chain.

- Example: A surge in demand for a new fashion trend leads to rapid and significant increases in orders up the supply chain, resulting in overproduction when the trend fades quickly.

- Order Batching in Manufacturing:

- A manufacturer places large, infrequent orders for raw materials to save on ordering costs, leading to variability and uncertainty for suppliers.

- Example: A car manufacturer orders steel in large batches, causing the steel supplier to experience significant fluctuations in demand.

- Price Promotions in Retail:

- Retailers running promotions or discounts can cause spikes in consumer buying, which are not indicative of long-term demand patterns. This can lead to manufacturers and suppliers ramping up production unnecessarily.

- Example: A supermarket’s promotion on canned goods leads to temporary demand spikes, causing the canned goods manufacturer to increase production, only to face excess inventory later.

- Rationing During Shortages:

- During product shortages, companies might over-order, anticipating limited availability, which exacerbates the shortage and leads to further order variability.

- Example: During a shortage of electronic components, electronics manufacturers place larger orders than needed, worsening the shortage and leading to increased variability in component demand.

Importance of Managing the Bullwhip Effect

Effectively managing the bullwhip effect is essential for maintaining supply chain efficiency and cost-effectiveness. It helps in aligning production with actual market demand, reducing inventory costs, improving customer service, and enhancing overall supply chain resilience.

In conclusion, the bullwhip effect is a critical concept in supply chain management, illustrating how small changes in demand can lead to larger and more significant fluctuations up the supply chain. Understanding its causes and implementing strategies to mitigate its impact are vital for effective supply chain management.