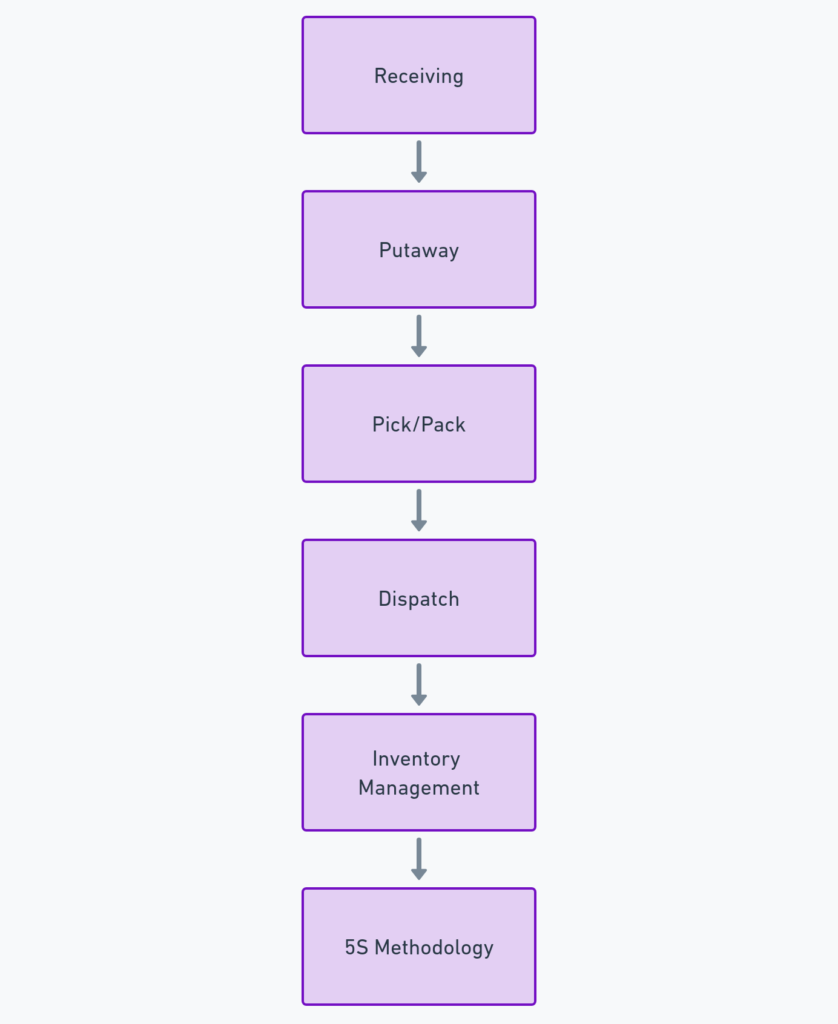

Warehouse management operations are a critical aspect of supply chain management, focusing on the efficient handling and storage of goods within a warehouse. These operations encompass a range of activities, from receiving and storing goods to picking, packing, and dispatching orders. Effective warehouse management is essential for maintaining inventory accuracy, optimizing space utilization, and ensuring timely order fulfillment, all of which contribute significantly to the overall efficiency of the supply chain.

Key Components of Warehouse Management Operations

- Receiving:

- The receiving process is the first step in warehouse operations. It involves accepting incoming goods, inspecting them for quality and quantity, and verifying them against purchase orders. Proper receiving is crucial for ensuring that inventory records are accurate and that goods are available for storage or processing.

- Example: A large retailer implements a barcode scanning system at the receiving dock to quickly and accurately record incoming shipments, reducing errors and speeding up the receiving process.

- Putaway:

- After goods are received, they are moved to their designated storage locations in the warehouse. Efficient putaway processes are essential for maximizing space utilization, organizing inventory for easy access, and maintaining order within the warehouse.

- Example: An e-commerce company uses a warehouse management system (WMS) to optimize putaway, directing workers to the most appropriate storage locations based on product characteristics and demand patterns.

- Pick/Pack:

- Picking involves retrieving items from storage locations to fulfill customer orders. Packing is the process of preparing these items for shipment, ensuring they are securely and appropriately packaged. Efficient pick/pack operations are crucial for quick and accurate order fulfillment.

- Example: A distribution center for a fashion brand implements a zone picking strategy, where workers are assigned specific areas of the warehouse, reducing travel time and increasing picking efficiency.

- Dispatch:

- Dispatch involves the final preparation and loading of goods for shipment to customers or other destinations. Effective dispatch processes ensure that orders are delivered on time and in good condition, contributing to customer satisfaction.

- Example: A manufacturing company uses an advanced scheduling system to coordinate dispatch activities, ensuring that trucks are loaded efficiently and depart on schedule.

- Inventory Management:

- Managing inventory levels is essential to meet demand without overstocking or understocking. This includes tracking inventory, forecasting demand, and conducting regular stock audits to ensure inventory accuracy.

- Example: A supermarket chain implements a just-in-time (JIT) inventory system, reducing excess stock and minimizing storage costs while ensuring product availability.

- 5S Methodology:

- The 5S methodology is a lean management tool used to organize and maintain a clean, efficient, and safe warehouse. The 5S stands for Sort, Set in order, Shine, Standardize, and Sustain. Implementing 5S helps in reducing waste, improving productivity, and creating a safer work environment.

- Example: A logistics company adopts the 5S methodology in its warehouses, leading to a more organized workspace, reduced search time for items, and improved safety for employees.

Importance of Effective Warehouse Management Operations

- Optimizing Storage Space:

- Efficient warehouse management operations help in optimizing the use of available storage space, enabling companies to store more goods in less space and reducing the need for additional warehousing facilities.

- Example: A furniture retailer reorganizes its warehouse layout using vertical storage solutions, significantly increasing storage capacity.

- Improving Order Accuracy:

- Accurate picking and packing processes are essential for ensuring that customers receive the correct items in their orders. This accuracy is crucial for customer satisfaction and reducing the costs associated with returns and exchanges.

- Example: An online electronics store implements a double-check system where each order is verified by two different employees, drastically reducing order errors.

- Reducing Costs:

- Effective warehouse management can lead to significant cost savings by reducing labor costs, minimizing inventory carrying costs, and optimizing other operational expenses.

- Example: A pharmaceutical distributor uses automated storage and retrieval systems (AS/RS) in its warehouse, reducing labor costs and improving storage density.

- Enhancing Customer Satisfaction:

- Timely and accurate order fulfillment directly impacts customer satisfaction. Efficient warehouse operations ensure that customers receive their orders quickly and without errors, leading to repeat business and positive reviews.

- Example: A specialty food company implements real-time inventory tracking, enabling it to provide accurate delivery estimates to customers, enhancing their shopping experience.

In conclusion, effective warehouse management operations are vital for the success of any business that involves the storage and distribution of goods. By optimizing these operations, companies can achieve greater efficiency, accuracy, and cost-effectiveness, ultimately enhancing their competitiveness in the market. Implementing best practices, leveraging technology, and adopting methodologies like 5S are key strategies for achieving excellence in warehouse management.