Organisations have more than ever realised the need to leverage the strategic importance of managing their supply base (Terpand et al, 2008). Activities with suppliers in terms of knowledge exchanges and feedback are perquisites to successful supplier development programs (Modi & Mabert, 2005). This piece focuses on the supplier feedback element. It will give examples of successful supplier feedback mechanisms and how businesses can automate the process. How this approach has allowed businesses to improve operations and service delivery. In the automotive sector an average of one day to one week is spent on supplier development. Honda and Toyota spend on average 13 weeks (Liker & Choi, 2004). This emphasizes the point of developing a robust feedback mechanism with suppliers. People on the ground at the execution end can provide better insight when developing a robust supply chain strategy aligned with top-down director level strategic objectives. The feedback from resources learning from day-to-day operations at the execution level is called the Bottom-up approach to operations strategy (Slack et al, 2019). Micraytech is a meteorological equipment manufacturer. The continual product and system innovation was having the effect of dramatically increasing its costs. These rising costs impacted profitability at an unacceptable level. Having variety in production usually impacts costs, therefore engineers worked with suppliers to develop modular products with customisation right at the end. This brought down costs and standardised product design. This is an example of a pure “bottom-up” approach. Initially, no top-level board decision was taken to initiate this practice. Nevertheless, it emerged as the way in which a company’s design engineers learned from their experience and used that learning to build their knowledge of how to lower some of the costs of innovation (Slack, 2019).

This piece will keep in mind the cost of operations as every second of a procurement practitioner’s productivity should be considered. The approach we will use is called robotic process automation RPA. This is a feature in Microsoft outlook. The adoption trend exhibits an exponential growth pattern from USD 183 million in 2016 to USD 1 Billion in 2022 (Statista, 2022). Software and development give a brief competitive edge to businesses. The ticketing allocation system of American Airlines is an example which helped gain greater market share as compared to its competitors United and Delta Airlines still using a manual ticket booking mechanism. However, these advantages can only be transient as IT hardware, software, automation, and artificial intelligence can give maximum advantage to early adopters (Carr, 2004)

The importance of adoption in terms of feedback and automation of processes has been dealt with. This section will deal with the best practices when developing a feedback questionnaire designed for suppliers The questions can vary from industry to industry. The questions are tailored based on my experience. This can be created on a standard google form link or Microsoft outlook form.

- Please the name of your organisation

- Please state your name.

- Please select the materials supplied.

- Please rate on a scale of 1 to 5 satisfaction levels on buyers’ performance

- Highlight the problems/issues faced during the supply process.

- Please rate the reliability of the buying organisation on a scale of 1 to 5.

- Please recommend any changes in process from the buyer’s side to improve your production lead times and reduce prices.

Developing an RPA for automating emails. The last section snapshots with a description on how to setup an RPA with your suppliers. This will ensure that the email with the form link is sent out every month to selected suppliers automatically. The responses from the questions can be recorded on a sharable spread sheet. Further enhancements could be done at later stages where data could be used to visualise the outcomes.

Step 1 Login to Office.com

Figure 1

Step 2 Selection of Power Automate Application

Figure 3

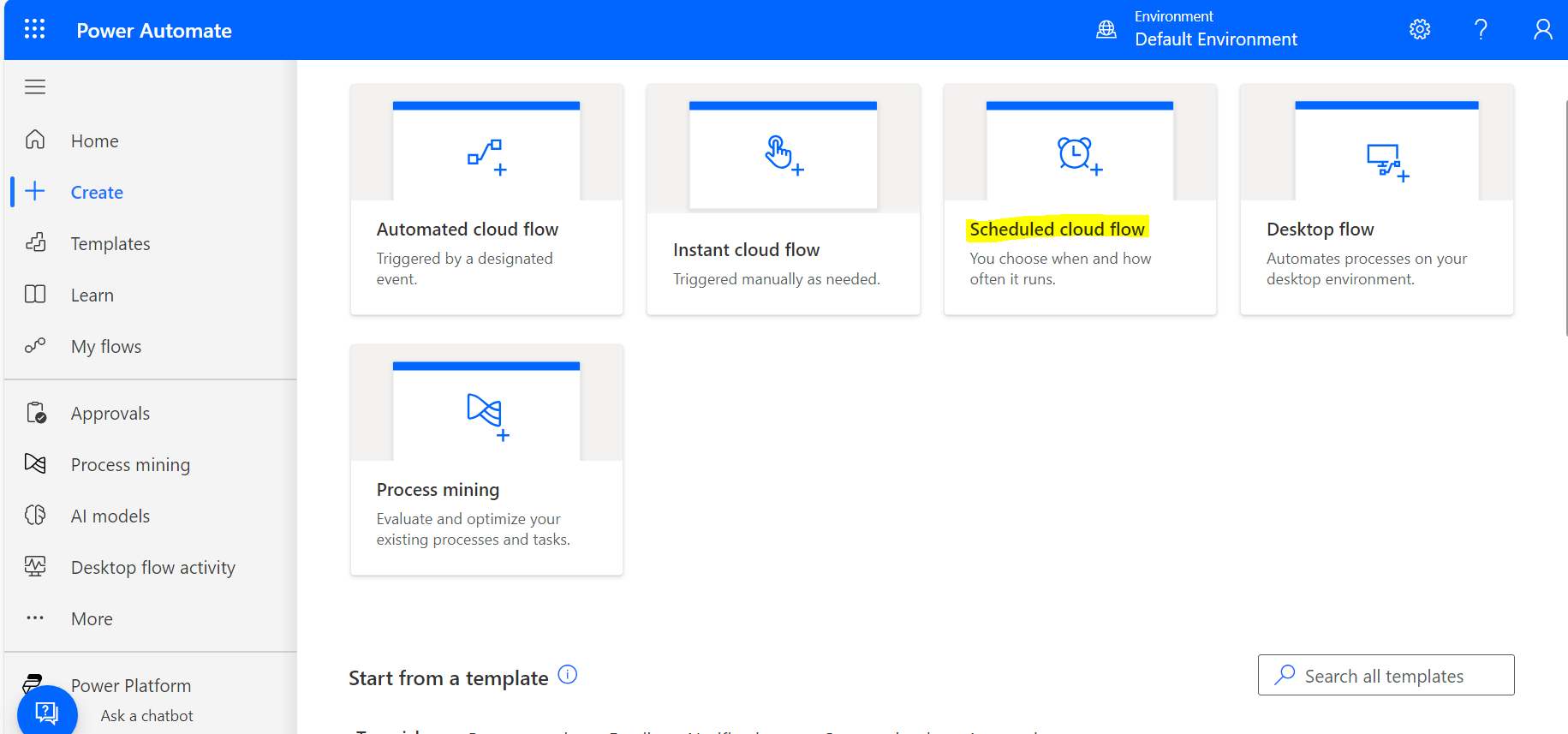

Step 3 Select the create on the Power Automate window.

Figure 4

Step 5 Select cloud flow.

Figure 5

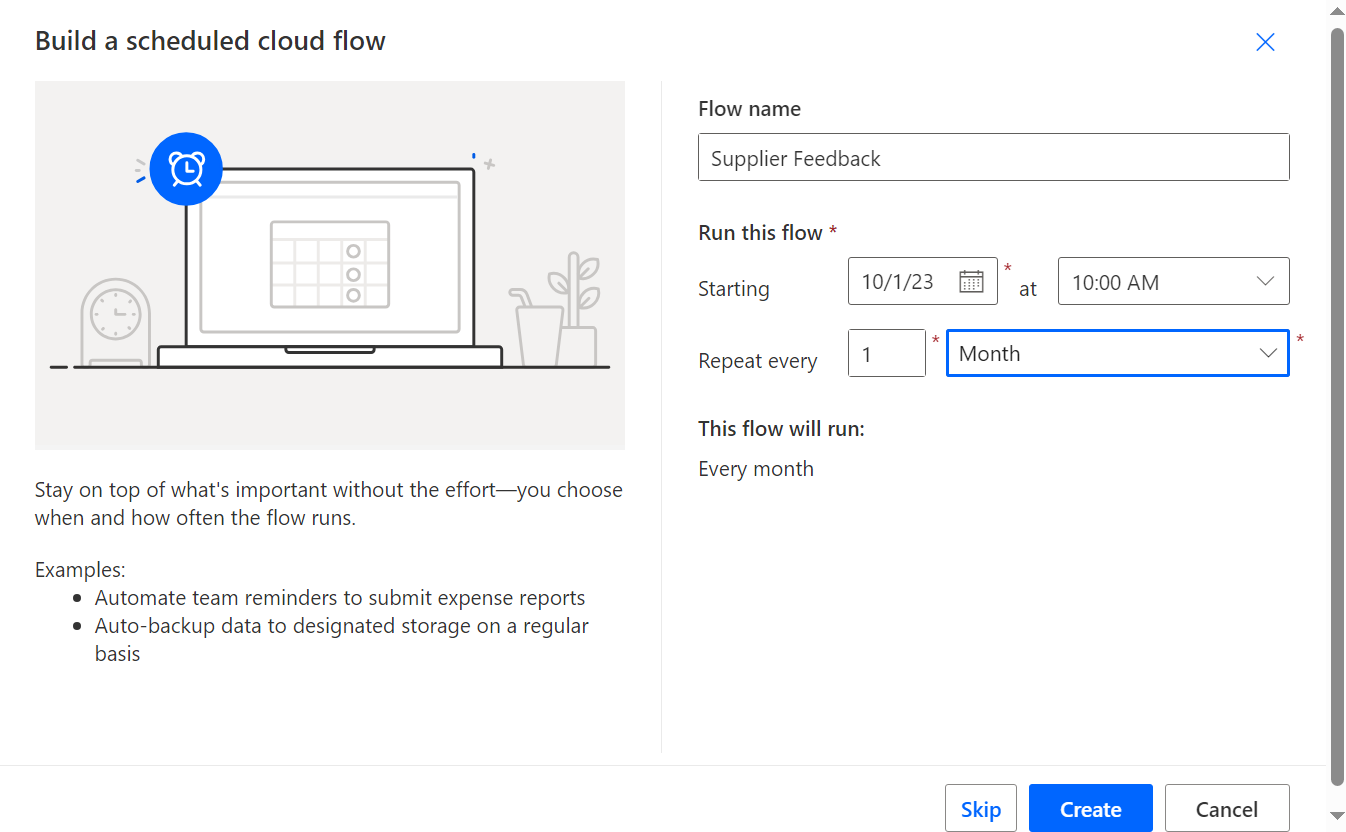

Step 6 Specify Name for the Flow I have named the flow as “Supplier Feedback”. I am scheduling the email every month starting from 1/10/2023 at 10:00 AM.

Figure 6

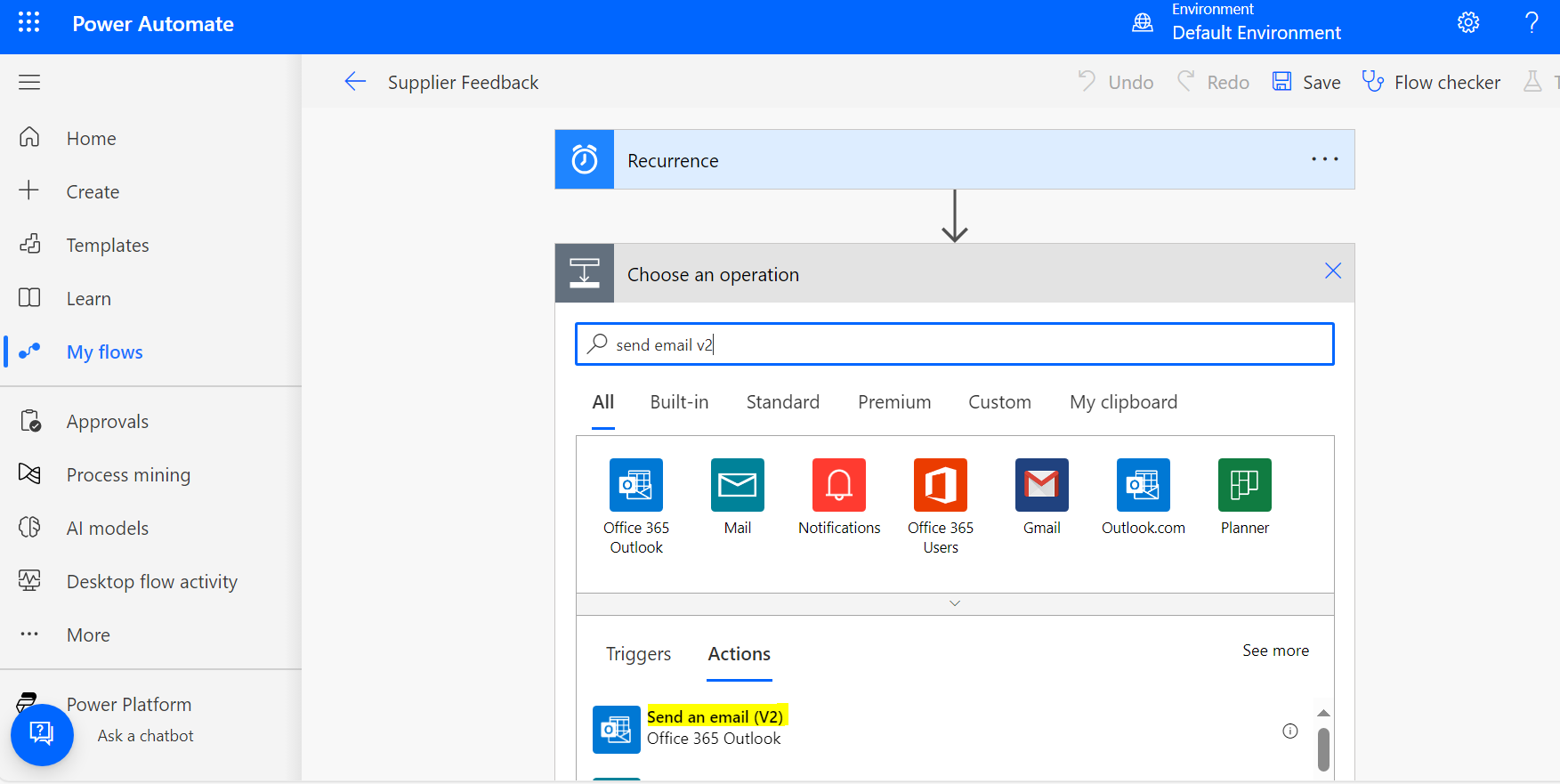

Step 7 Select the next step and select *select an email v2’. This will then be used to develop the body of the email.

Figure 7

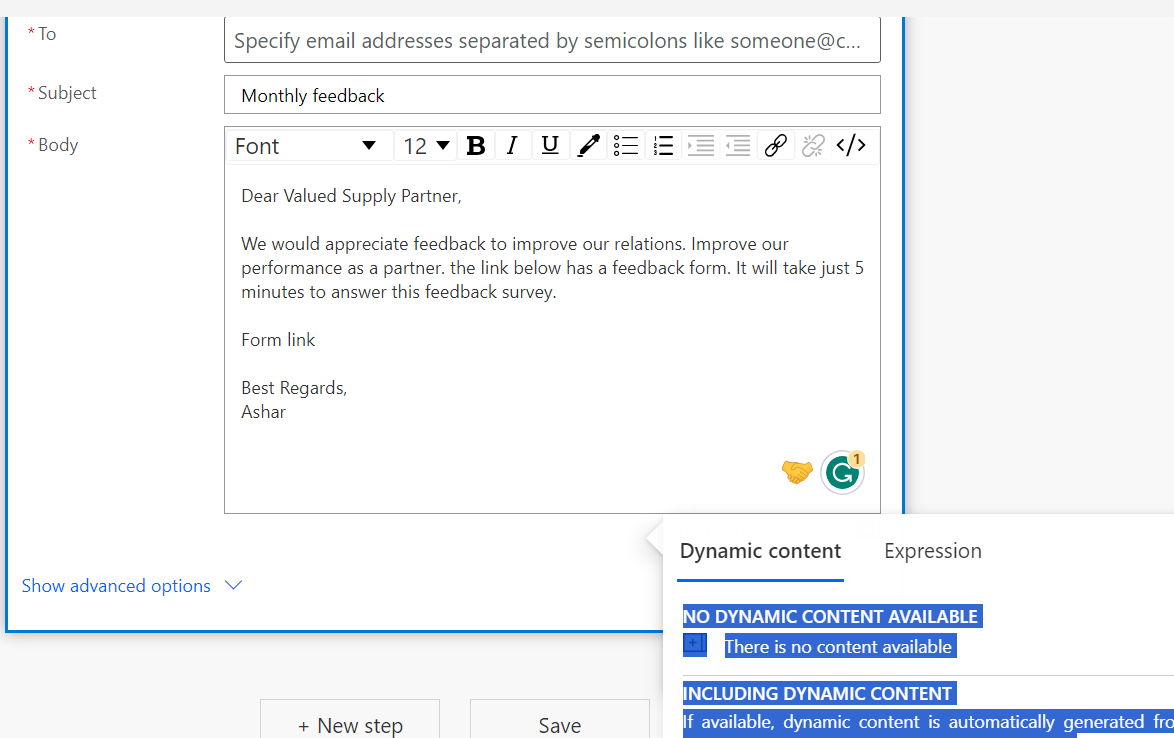

Step 8 Design email for supplier feedback

Figure 8

Once saved a periodic email will be sent on the 1st of every month.

An organization’s competitive advantage not only lies in the cost but also in the value it generates. The most significant impact is the strategy it employs to provide superior value in the eyes of the Customer (Cristopher, 2016, p.10). Our approach can further simplify the process of obtaining constructive criticism and enhance performance. Furthermore, the automation-based approach does not require time to be spent by the buyer.

References

Terpend, R., Tyler, B.B., Krause, D.R. and Handfield, R.B. (2008), “Buyer-supplier relationships: derived value over two decades”, Journal of Supply Chain Management, Vol. 44 No. 2, pp. 28-48.

Modi, S.B. and Mabert, V.A. (2005), “Supplier development: improving supplier performance through knowledge transfer”, Journal of Operations Management, Vol. 25, pp. 42-64

Taylor, P. (2022) Global Robotic Process Automation Market by segment 2022, Statista. Available at: https://www.statista.com/statistics/740584/worldwide-robotic-process-automation-market-size-by-segment/ (Accessed: 01 October 2023).

Carr, N.G., 2004. Does IT matter?: information technology and the corrosion of competitive advantage. Harvard Business Press.

Liker, J. and Choi, T.Y. (2014) Building deep supplier relationships, Harvard Business Review. Available at: https://hbr.org/2004/12/building-deep-supplier-relationships (Accessed: 01 October 2023).

Slack, N. and Brandon-Jones, A. (2019) Operations management. Harlow, Essex: Pearson Education Limited.

Cristopher, M. (2016). Logistics & Supply Chain Management. 5th ed. United Kingdom: Pearson Education Limited, p.10.